High-Octane Motorsports e.V. is a registered, nonprofit organisation and also a university group at Friedrich-Alexander-Universität Erlangen-Nürnberg.

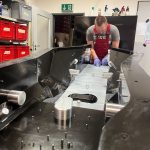

As a Formula Student team, we have been building an innovative race car every year since our foundation in 2007. All tasks necessary to achieve this goal are solved within the club and without any professional help. Our members develop their own concept, design in CAD and manufacture the race car. The car undergoes various tests before the races to ensure safety and performance. The club is composed of students from all faculties of the university, who work independently to acquire specialized knowledge and learn practically about automotive engineering, manufacturing technologies and economics. This interdisciplinary combination of the technical and economic fields is unique and a characteristic of Formula Student, in which the race car is evaluated not only from a technical point of view, but also from a financial one.

Formula Student is a racing series departed in three different categories. In these categories electric, combustion and driverless vehicles compete against each other. High-Octane Motorsports e.V. represents the FAU in the combustion and driverless class (since 2018). There are different international events in countries all over the world and the competitions take place on famous tracks, like the Formula Student Germany at the Hockenheimring or the historic Silverstone track. With the example of Formula Student Germany we want to explain the different disciplines and the process of the events.

The Accelertion event is a accelerating race for 75 meter. The fastest teams reach the finish line often in less than 4 seconds. Even though this event seems to be the easiest one, the Acceleration hat great technical challenges. Engine torque, drive and traction have to be perfectly balanced to enable an optimal speed and prevent wheelspin.

The SkidPad-Course is probably the most striking course in motor sport and is best described as an infinity sign. The shape of the course demands a high cross acceleration and at the same time good handling as the circles only have a diameter of 15 meter. The driver has to complete two consecutive laps as fast as possible, while the shearing force of up to 1.4 g are affecting the car.

In this discipline the team has to defend their design decisions in front of the judges, which are representatives from the industry and motor sport. For this event forward-looking Ideas and lots of simulation are requested in the development phase. The looks of the car and its components are only judged on technical topics, where innovation is very important for the success.

In the Cost and Manufacturing event a cost report has to be developed on which base the teams cost efficiency can be compared. This cost report includes a listing of all materials and parts as well as the working hours that are needed to build the car. So this report shows the overall costs of the projects. During the presentation for the judges the team also has to explain their knowledge about cost efficient working.